Bayanan Bayani na FRP

WELLGRID abokin aikin injiniyan ku ne don titin hannun FRP, titin tsaro, tsani da buƙatun samfur. Ƙwararrun injiniyanmu da ƙungiyar tsarawa za su iya taimaka maka samun mafita mai kyau wanda ya dace da bukatun ku don tsawon rai, aminci da farashi.

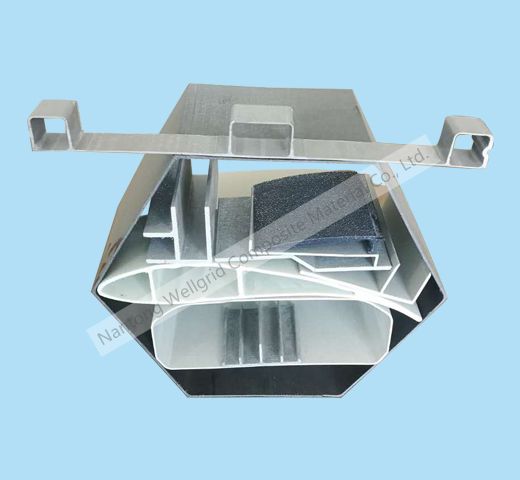

Siffofin

Haske zuwa nauyi

Fam-domin-laba, Siffofin tsarin fiberglass ɗin mu da aka zube sun fi ƙarfin ƙarfe a cikin shugabanci mai tsayi. FRP ɗinmu tana da nauyi har zuwa 75% ƙasa da ƙarfe da 30% ƙasa da aluminium - manufa lokacin ƙidayar nauyi da aiki.

Sauƙin Shigarwa

Farashin FRP akan matsakaita 20% kasa da karfe don shigarwa tare da ƙarancin lokaci, ƙarancin kayan aiki, da ƙarancin aiki na musamman. Guji ƙwaƙƙwaran ƙwaƙƙwal masu tsada da kayan aiki masu nauyi, da hanzarta aikin gini ta amfani da samfuran sifofi.

Lalacewar sinadarai

Abubuwan haɗin fiber da aka ƙarfafa polymer (FRP) suna ba da juriya ga kewayon sinadarai da matsananciyar yanayi. Muna ba da cikakken jagorar juriya na lalata don tabbatar da aikin samfuran sa a cikin wasu yanayi mafi wahala.

Kulawa Kyauta

FRP yana da dorewa kuma yana da juriya. Ba zai barke ko gurɓata kamar karafa ba. Yana tsayayya da lalacewa da lalata, yana kawar da buƙatar kulawa akai-akai. Wannan haɗin gwiwar aiki da karko yana ba da kyakkyawan bayani a cikin aikace-aikace masu yawa.

Tsawon Rayuwa

Kayayyakinmu suna ba da ƙwaƙƙwaran ƙarfi da juriya na lalata a cikin aikace-aikacen buƙatu, suna ba da ingantaccen rayuwar samfur fiye da kayan gargajiya. Tsawon rayuwar samfuran FRP yana ba da tanadin farashi akan tsarin rayuwar samfurin. Farashin da aka shigar ya ragu saboda sauƙin shigarwa. Kudin kulawa yana raguwa saboda ƙarancin lokaci a wuraren da ake buƙatar kulawa, kuma an kawar da farashin cirewa, zubarwa, da maye gurbin gurɓataccen gurɓataccen ƙarfe.

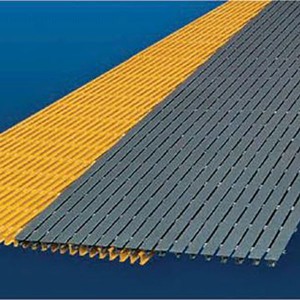

Babban Ƙarfi

FRP yana da babban rabo mai ƙarfi zuwa nauyi idan aka kwatanta da kayan gargajiya kamar ƙarfe, siminti da itace. Za a iya ƙirƙira gratings na FRP don su kasance masu ƙarfi don ɗaukar lodin abin hawa yayin da suke ƙasa da rabin nauyin nau'in grating na karfe.

Resistant Tasiri

FRP na iya jure babban tasiri tare da lalacewa mara kyau. Muna ba da gratings masu ɗorewa sosai don gamsar da mafi tsananin buƙatun tasiri.

Wutar Lantarki & Ƙarƙashin Ƙarƙashin Ƙarfafawa

FRP ba shi da wutar lantarki wanda ke haifar da ƙarin aminci idan aka kwatanta da kayan aiki (watau ƙarfe). Hakanan FRP yana da ƙarancin ƙarancin zafin jiki (canja wurin zafi yana faruwa a ƙaramin ƙima), yana haifar da mafi kyawun saman samfurin lokacin saduwa ta jiki.

Wuta Retardant

An ƙera samfuran FRP don samun yaduwar harshen wuta 25 ko ƙasa da haka kamar yadda aka gwada daidai da ASTM E-84. Hakanan sun cika ka'idodin kashe kansu na ASTM D-635.

Slip Resistant

Kayan aikin mu da aka ƙera su da tarkace da samfuran matattakala suna ba da mafi kyawun ƙafar ƙafar ƙafa a cikin rigar da mahalli mai mai. Karfe yana zama m lokacin mai mai ko jika, amma gratings ɗinmu suna da masana'anta mafi girma kuma suna kasancewa lafiya ko da a jike.

Kayayyakin mu masu juriya na zamewa suna ƙara aminci ga ma'aikata wanda zai haifar da ƙarancin hatsarori a wurin aiki da raguwar farashi mai alaƙa da rauni.

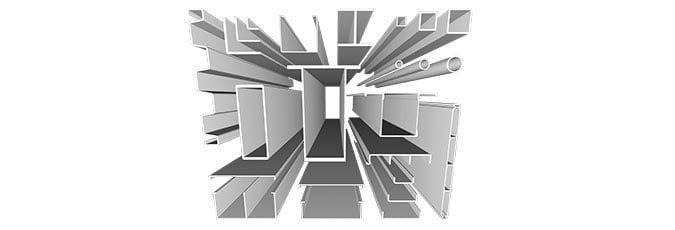

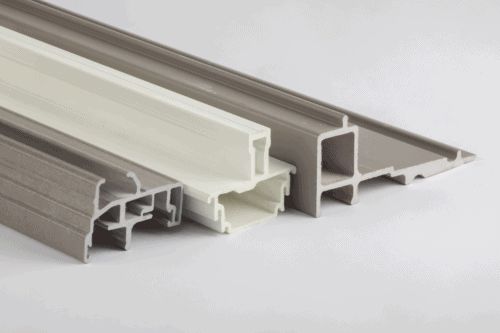

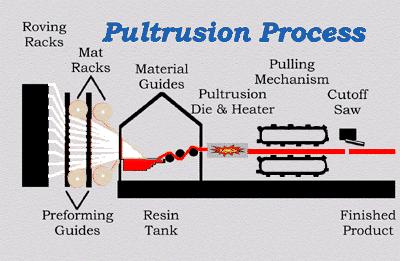

Ƙayyadaddun bayanai

Bayanan tsarin mu na pultrusion suna da babban ƙarfi da ma'auni a tsayin tsayi (LW) da crosswise (CW) kuma sun dace da ƙa'idodin Turai da Amurka masu dacewa; Ana amfani da su sosai a ƙasashen waje a cikin hasumiya mai sanyaya, masana'antar wutar lantarki. Da fatan za a tuntuɓe mu don samun cikakkun bayanai don bayanan tsarin pultrusion.

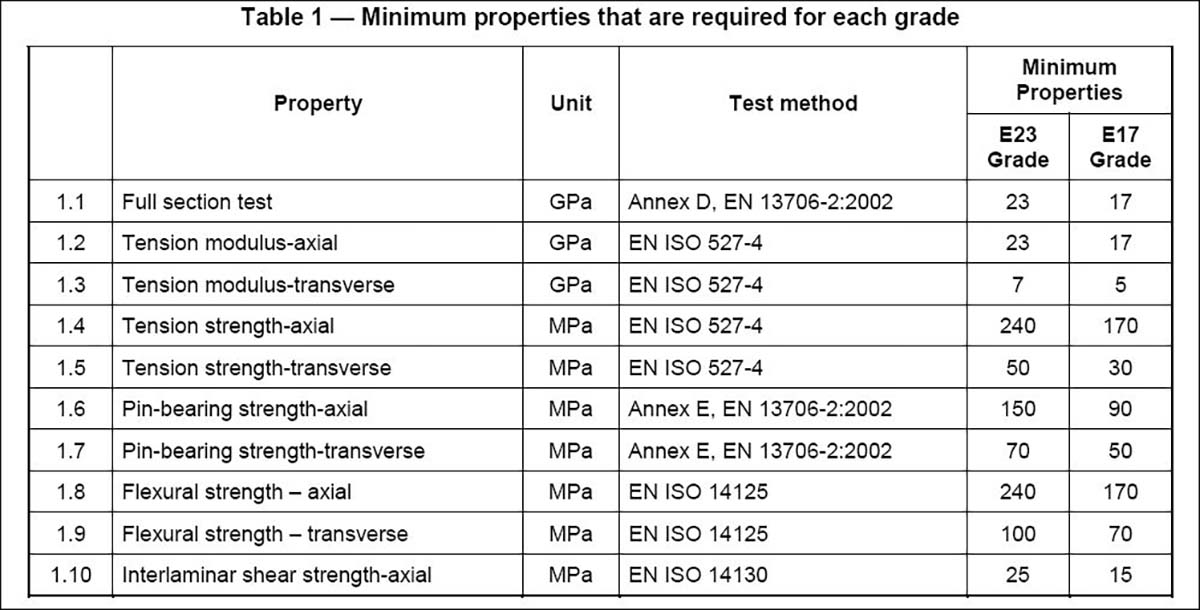

Muna ba da bayanan martaba na FRP pultrusion sun haɗu da daidaitattun EN 13706 tare da kaddarorin ƙasa.

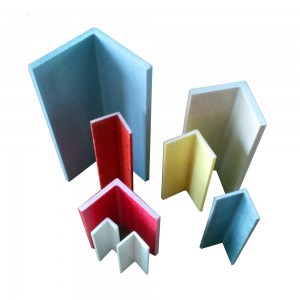

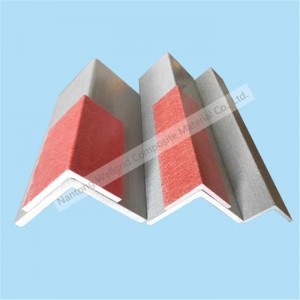

| Angle | H (mm) | B(mm) da | T1(mm) da | T2(mm) da | (mm²) | (g/m) |

| 25 | 25 | 3.2 | 3.2 | 153 | 290 | |

| 30 | 20 | 4 | 4 | 184 | 350 | |

| 30 | 30 | 3 | 3 | 171 | 325 | |

| 40 | 22 | 4 | 4 | 232 | 440 | |

| 40 | 40 | 4 | 4 | 304 | 578 | |

| 40 | 40 | 8 | 8 | 574 | 1090 | |

| 50 | 50 | 5 | 5 | 475 | 902 | |

| 50 | 50 | 6.4 | 6.4 | 604 | 1147 | |

| 76 | 76 | 6.4 | 6.4 | 940 | 1786 | |

| 76 | 76 | 9.5 | 9.5 | 1367 | 2597 | |

| 101 | 101 | 6.4 | 6.4 | 1253 | 2380 | |

| 101 | 101 | 9.5 | 9.5 | 1850 | 3515 | |

| 101 | 101 | 12.7 | 12.7 | 2425 | 4607 | |

| 152 | 152 | 9.5 | 9.5 | 2815 | 5348 | |

| 152 | 152 | 12.7 | 12.7 | 3730 | 7087 | |

| 220 | 72 | 8 | 8 | 2274 | 4320 |

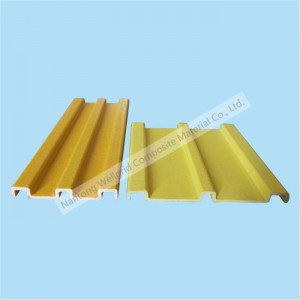

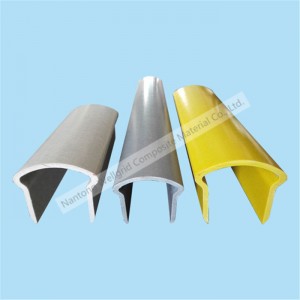

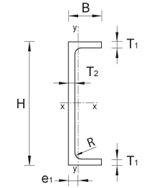

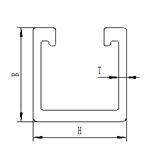

| Tashoshi | H (mm) | B (mm) | T1 (mm) | T2 (mm) | (mm²) | (g/m) |

|

| 40 | 20 | 4 | 4 | 289 | 550 |

| 50 | 14 | 3 | 3 | 220 | 418 | |

| 75 | 25 | 5 | 5 | 576 | 1094 | |

| 76 | 38 | 6.4 | 6.4 | 901 | 1712 | |

| 80 | 30 | 3.1 | 3.1 | 405 | 770 | |

| 101 | 35 | 3.2 | 3.2 | 529 | 1006 | |

| 101 | 48 | 3.2 | 3.2 | 613 | 1165 | |

| 101 | 30 | 6.4 | 6.4 | 937 | 1780 | |

| 101 | 44 | 6.4 | 6.4 | 1116 | 2120 | |

| 150 | 50 | 6 | 6 | 1426 | 2710 | |

| 152 | 35 | 4.8 | 4.8 | 1019 | 1937 | |

| 152 | 48 | 4.8 | 4.8 | 1142 | 2170 | |

| 152 | 42 | 6.4 | 6.4 | 1368 | 2600 | |

| 152 | 45 | 8 | 8 | 1835 | 3486 | |

| 152 | 42 | 9.5 | 9.5 | 2077 | 3946 | |

| 178 | 60 | 6.4 | 6.4 | 1841 | 3498 | |

| 203 | 55 | 6.4 | 6.4 | 1911 | 3630 | |

| 203 | 55 | 9.5 | 9.5 | 2836 | 5388 | |

| 254 | 72 | 12.7 | 12.7 | 4794 | 9108 |

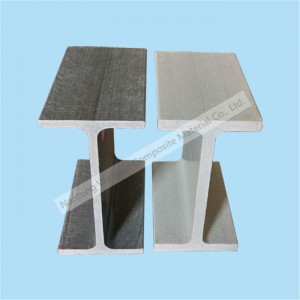

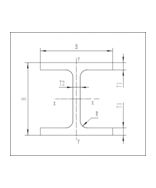

| Ina Beam | H(mm) | B(mm) | T1(mm) | T2(mm) | (mm²) | (g/m) |

| 25 | 15 | 4 | 4 | 201 | 381 |

| 38 | 15 | 4 | 4 | 253 | 480 | |

| 50 | 15 | 4 | 4 | 301 | 571 | |

| 76 | 38 | 6.4 | 6.4 | 921 | 1749 | |

| 102 | 51 | 6.4 | 6.4 | 1263 | 2400 | |

| 152 | 76 | 6.4 | 6.4 | 1889 | 3590 | |

| 152 | 76 | 9.5 | 9.5 | 2800 | 5320 | |

| 203 | 101 | 9.5 | 9.5 | 3821 | 7260 | |

| 203 | 101 | 12.7 | 12.7 | 5079 | 9650 | |

| 254 | 127 | 9.5 | 9.5 | 4737 | 9000 | |

| 254 | 127 | 12.7 | 12.7 | 6289 | 11950 | |

| 305 | 152 | 9.5 | 9.5 | 5653 | 10740 | |

| 305 | 152 | 12.7 | 12.7 | 7526 | 14300 |

| Farashin WFB | H(mm) | B(mm) | T1(mm) | T2(mm) | (mm²) | (g/m) |

| 76 | 76 | 6.4 | 6.4 | 1411 | 2680 |

| 102 | 102 | 6.4 | 6.4 | 1907 | 3623 | |

| 100 | 100 | 8 | 8 | 2342 | 4450 | |

| 152 | 152 | 6.4 | 6.4 | 2867 | 5447 | |

| 152 | 152 | 9.5 | 9.5 | 4250 | 8075 | |

| 203 | 203 | 9.5 | 9.5 | 5709 | 10847 | |

| 203 | 203 | 12.7 | 12.7 | 7558 | 14360 | |

| 254 | 254 | 9.5 | 9.5 | 7176 | 13634 | |

| 254 | 254 | 12.7 | 12.7 | 9501 | 18051 | |

| 305 | 305 | 9.5 | 9.5 | 8684 | 16500 | |

| 305 | 305 | 12.7 | 12.7 | 11316 | 21500 |

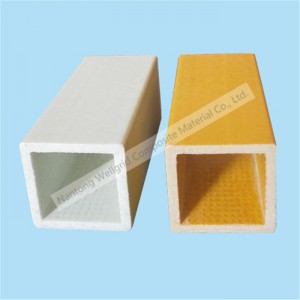

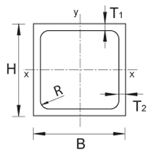

| Square tube | H (mm) | B (mm) | T1 (mm) | T2 (mm) | (mm²) | (g/m) |

| 15 | 15 | 2.5 | 2.5 | 125 | 237 | |

| 25.4 | 25.4 | 3.2 | 3.2 | 282 | 535 | |

| 30 | 30 | 5 | 5 | 500 | 950 | |

| 38 | 38 | 3.2 | 3.2 | 463 | 880 | |

| 38 | 38 | 6.4 | 6.4 | 811 | 1540 | |

| 40 | 40 | 4 | 4 | 608 | 1155 | |

| 40 | 40 | 6 | 6 | 816 | 1550 | |

| 44 | 44 | 3.2 | 3.2 | 521 | 990 | |

| 44 | 44 | 6.4 | 6.4 | 963 | 1830 | |

| 45 | 45 | 4 | 4 | 655 | 1245 | |

| 50 | 25 | 4 | 4 | 537 | 1020 | |

| 50 | 50 | 4 | 4 | 750 | 1425 | |

| 50 | 50 | 5 | 5 | 914 | 1736 | |

| 50 | 50 | 6.4 | 6.4 | 1130 | 2147 | |

| 54 | 54 | 5 | 5 | 979 | 1860 | |

| 60 | 60 | 5 | 5 | 1100 | 2090 | |

| 76 | 38 | 4 | 4 | 842 | 1600 | |

| 76 | 76 | 6.4 | 6.4 | 1795 | 3410 | |

| 76 | 76 | 9.5 | 9.5 | 2532 | 4810 | |

| 101 | 51 | 6.4 | 6.4 | 1779 | 3380 | |

| 101 | 76 | 6.4 | 6.4 | 2142 | 4070 | |

| 101 | 101 | 6.4 | 6.4 | 2421 | 4600 | |

| 101 | 101 | 8 | 8 | 2995 | 5690 | |

| 130 | 130 | 9 | 9 | 4353 | 8270 | |

| 150 | 150 | 5 | 5 | 2947 | 5600 | |

| 150 | 150 | 10 | 10 | 5674 | 10780 | |

| Zagaye tube | D1 (mm) | D2 (mm) | T (mm) | (mm²) | (g/m) |

|

| 19 | 14 | 2.5 | 128 | 245 |

| 24 | 19 | 2.5 | 168 | 320 | |

| 25.4 | 20.4 | 2.5 | 180 | 342 | |

| 30 | 24 | 3 | 254 | 482 | |

| 32 | 26 | 3 | 273 | 518 | |

| 40 | 32 | 4 | 452 | 858 | |

| 50 | 42 | 4 | 578 | 1098 | |

| 50 | 40 | 5 | 707 | 1343 | |

| 50 | 37.2 | 6.4 | 877 | 1666 | |

| 65 | 52.2 | 6.4 | 1178 | 2220 | |

| 76 | 63.2 | 6.4 | 1399 | 2658 | |

| 101 | 85 | 8 | 2337 | 4440 |

| Zagaye mai ƙarfi | D (mm) | (mm²) | (g/m) | |

| 7 | 38 | 72 | |

| 8 | 50 | 95 | ||

| 10 | 79 | 150 | ||

| 12 | 113 | 215 | ||

| 15 | 177 | 336 | ||

| 18 | 254 | 483 | ||

| 20 | 314 | 597 | ||

| 25 | 491 | 933 | ||

| 38 | 1133 | 2267 | ||

| Farantin karfe | B(mm) | H(mm) | T(mm) | (mm²) | (g/m) |

| 100 | 12 | 3 | 461 | 875 |

| 100 | 15 | 4 | 579 | 1100 | |

| 150 | 12 | 3 | 589 | 1120 |